With proper cooling in place, I needed to respond to the needs of my wife… Get this $#!+ off of my kitchen table. Well, not her exact words, but I can read between the lines. Actually, she has been great about it all. I have been fretting about what and where my Shapeoko will live. I was initially thinking about putting having it in the garage. I live in south eastern US and I can see that 1. I will not want to work down in the garage during the heat of the summer. 2. Seeing that polar vortexes seem to like the south, and as you may have seen a little snow can bring the our City to a skreeeeching halt. I will not want to be in the garage for long periods of time. So… looks like it will be in my workshop.

If I am going to be in the workshop that means I need a table. I just finished cleaning off the air hockey table a couple of weeks ago, so that was off limits. Air hockey tables are a high gravity catch all for anything that does not seem to have some other place to live. Dangerous things really. I designed the table to be sort of a box on legs. I wanted a ceiling on it to support the drivers, control box, tools and so on. It was designed to be long enough that I can grow the Shapeoko to 1 meter. Initially I will probably keep my laptop at the end of the table.

This was all originally supposed to sit on a couple of saw horses for the legs. After setting it up on the saw horses, the whole thing wobbled in an unsettling way. This is not exactly the sort of thing you want to be falling over mid milling job, so, I set off to build legs that were a little more proper, not to mention structural.

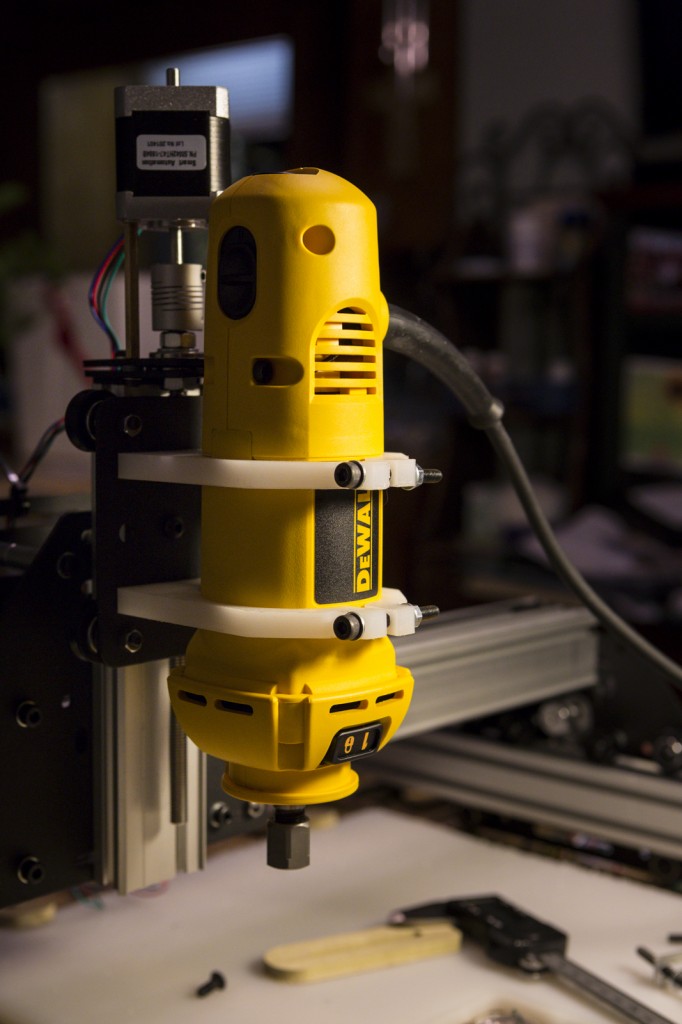

Something that is being thought about (heavily) in the back of my mind is how loud the spindle (Dewalt DW660 router) and the vacuum are. They are each quite loud by themselves, but together they are a whole new monster. They are both running around 90 dB. Sound containment was also considered in the design. While I will not be able to eliminate the noise completely, I would like to knock it down to tolerable levels (without the need for hearing protection). So essentially the sides are built as a cage to house sound panels on the sides. I will also be building a sound panel box for the vacuum as well. Once built they should be able to slide into place. I played with some panels I currently have to test a couple of ideas. I will cover this in another post though.